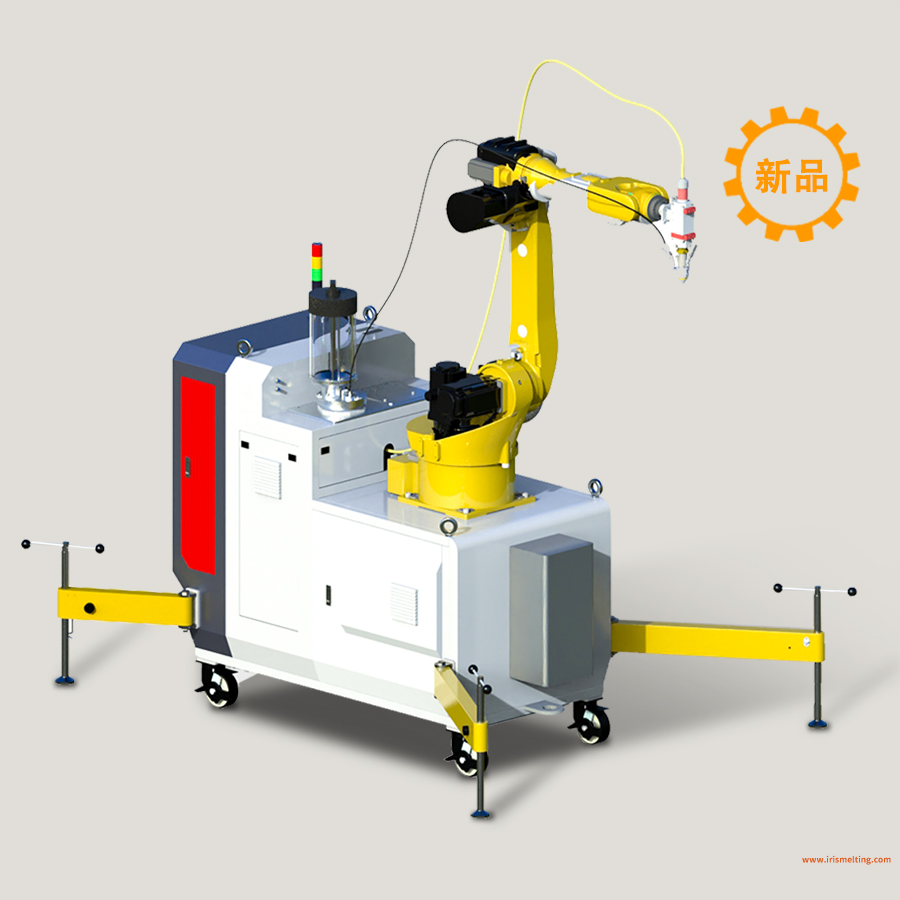

Product Description

Equipment advantages:1, equipped with six-axis robot, can achieve the expansion of the working radius, equipped with different motion systems to achieve all kinds of complex, large workpiece cladding processing operations;

2, modular integration, can quickly disassemble and assemble;

3, the equipment for the workpiece that can not be disassembled and transported on-site cladding/added processing has unparalleled advantages, such as large difficult to disassemble parts, large difficult to transport workpiece and on-site emergency repair and other online repair, such as turbine shaft diameter, rolling mill, large-scale hydraulic power generation, thermal power, nuclear power, chemical industry and other on-site repair.

4, high cladding efficiency, low heat input, fast cladding powder utilization rate ≥90%;

5. Metallurgical combination of cladding layer and substrate, dense organization, no porosity crack inclusion and other defects, low dilution rate, small heat affected zone;

6, the system is stable and reliable, and the cladding parameters are adjustable and controllable, which can realize the centralized control of laser, powder, gas and robot.

Medium Frequency Scrap Steel Induction Melting Furnace

Medium Frequency Scrap Steel Induction Melting Furnace Medium Frequency Scrap Copper Induction Melting Furnace

Medium Frequency Scrap Copper Induction Melting Furnace HF Induction Melting Gold Furnace

HF Induction Melting Gold Furnace continuous steel carburizing process furnace

continuous steel carburizing process furnace Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace

Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace Steel Copper aluminum Ingot Casting Machine

Steel Copper aluminum Ingot Casting Machine Gas Nitriding Furnace

Gas Nitriding Furnace The electromagnetic induction

The electromagnetic induction Roller heat treatment furnace

Roller heat treatment furnace  Top-opening industrial box-type heat treatment furnace

Top-opening industrial box-type heat treatment furnace