Product Description

Supply of complete equipment

1.A furnace body

2. One set power supply cabinet

3.A transformer

4.A vacuum pump

Main features

1. The furnace body has good sealing performance and low air leakage rate.

2. Good maneuverability and high degree of automation.

3. Pulse issuance and duty cycle adjustment, written by software, with high equipment stability.

4. The vacuum pump is adjusted by frequency conversion, the vacuum degree control precision is high, and the mechanical wear of the vacuum pump is greatly reduced.

5. The cause of the failure can be displayed directly on the display screen, and the troubleshooting is fast.

6. It can be controlled remotely (mobile phone), which is convenient for opening the furnace.

Ion nitridation process flow

1.Workpiece preparation

2.Place the workpiece on the workbench and close the furnace

3.Vacuum to 10mpa

4.Add voltage 400-600V

5.When the workpiece is heated to 100℃, add nitrogen and hydrogen (the amount of gas introduced is 801/h), and then rise the temperature to 520℃

6.Nitrogen atoms partially penetrate into the workpiece under the acceleration of the electric field, and hydrogen atoms combine with trace oxygen atoms to form water

7.The nitrogen atoms that are not involved are combined into nitrogen molecules, the hydrogen atoms that are not involved are combined into hydrogen molecules, the hydrogen atoms are combined with a trace amount of oxygen atoms to form water, and the three mixed gases are discharged from the furnace body through a vacuum pump

8.After 8-10 hours of heat preservation at 520 ℃, turn off the gas supply, turn off the vacuum pump, turn off the power supply, and the workpiece cools with the furnace

9.When the temperature of the workpiece drops below 200℃ , put air into the furnace to make the furnace reach atmospheric pressure, lift the furnace body, take out the workpiece, and finish nitriding.

Plasma Ion nitriding furnace details

Comparison of workpiece before and after nitriding

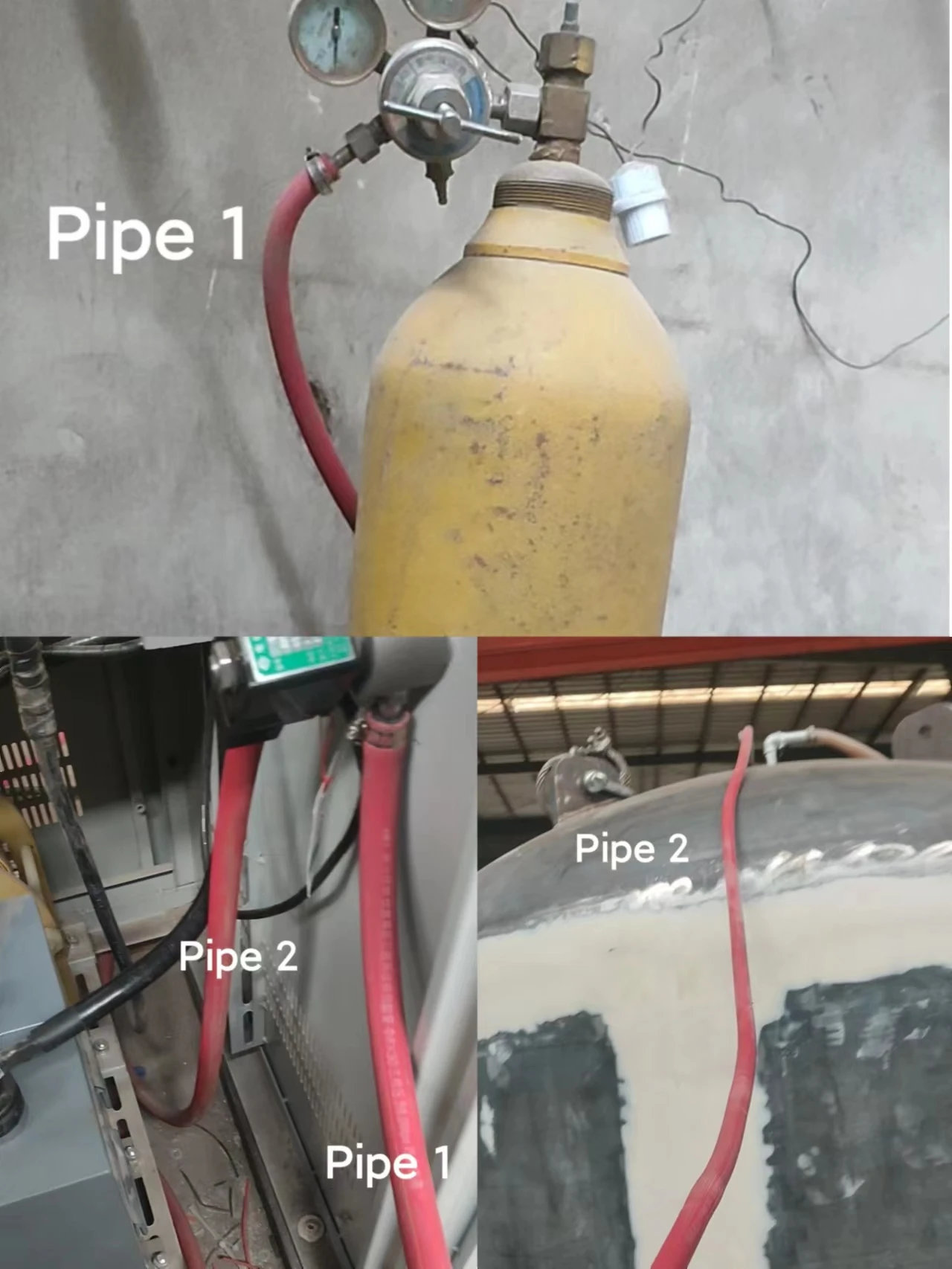

The Gas connection of the plasma ion nitriding furnace

|

Product name |

unit |

25A |

50A |

75A |

100A |

|

Ultimate vacuum |

Pa |

6.67 |

|||

|

Pressure rise rate |

Pa/min |

0.0133 |

|||

|

Vacuum pump |

pc |

2x-4 |

2x-8 |

2x-8 |

2x-8 |

|

2x-4 |

2x-8 |

2x-8 |

2x-15 |

||

|

Furnace chamber size |

mm |

Φ760*800 |

Φ1060*950 |

Φ920*1200 |

Φ1100*1200 |

|

Maximum heating area |

cm² |

1.25*104 |

2.5*104 |

3.5*104 |

5*104 |

|

loading capacity |

Kg |

600 |

800 |

1000 |

1200 |

|

Maximum operating temperature |

℃ |

650 |

650 |

650 |

|

Medium Frequency Scrap Steel Induction Melting Furnace

Medium Frequency Scrap Steel Induction Melting Furnace Medium Frequency Scrap Copper Induction Melting Furnace

Medium Frequency Scrap Copper Induction Melting Furnace HF Induction Melting Gold Furnace

HF Induction Melting Gold Furnace continuous steel carburizing process furnace

continuous steel carburizing process furnace Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace

Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace Steel Copper aluminum Ingot Casting Machine

Steel Copper aluminum Ingot Casting Machine Gas Nitriding Furnace

Gas Nitriding Furnace The electromagnetic induction

The electromagnetic induction Roller heat treatment furnace

Roller heat treatment furnace  Top-opening industrial box-type heat treatment furnace

Top-opening industrial box-type heat treatment furnace